CNC wood panel processing machines

CNC machines are infinitely versatile but for making cabinetry a class of CNC known as a "vertical processing centre" or a "machining centre" suits a cabinetry workshop better. The features of these machines include:

- loads a single panel at a time. Fixturing panels in a CNC takes time whereas with a machining centre individual panels are fed in (after been cut to size and edgebanded) and processed.

- toolchanger loaded with most frequently used cabinetry tools including 3, 5, 8 and 35mm drill bits

- capable of end-drilling e.g. drill 8mm diameter dowel holes in end of a panel. A seemlingly simple operation but something that a flat-bed CNC struggles with

These types of machine and what they can do are commonly referred to as CNC drilling.

The two machining file formats we support are:

- TCN files - Felder machine preferred format

- WoodWOP / MPR files - Homag machine preferred format

CNC Machine examples

These machines have been used with Cabcode drilling files. Other machines that support TCN and WoodWOP / MPR files will work too.- TCN files - Felder Creator 950, Vitap K2

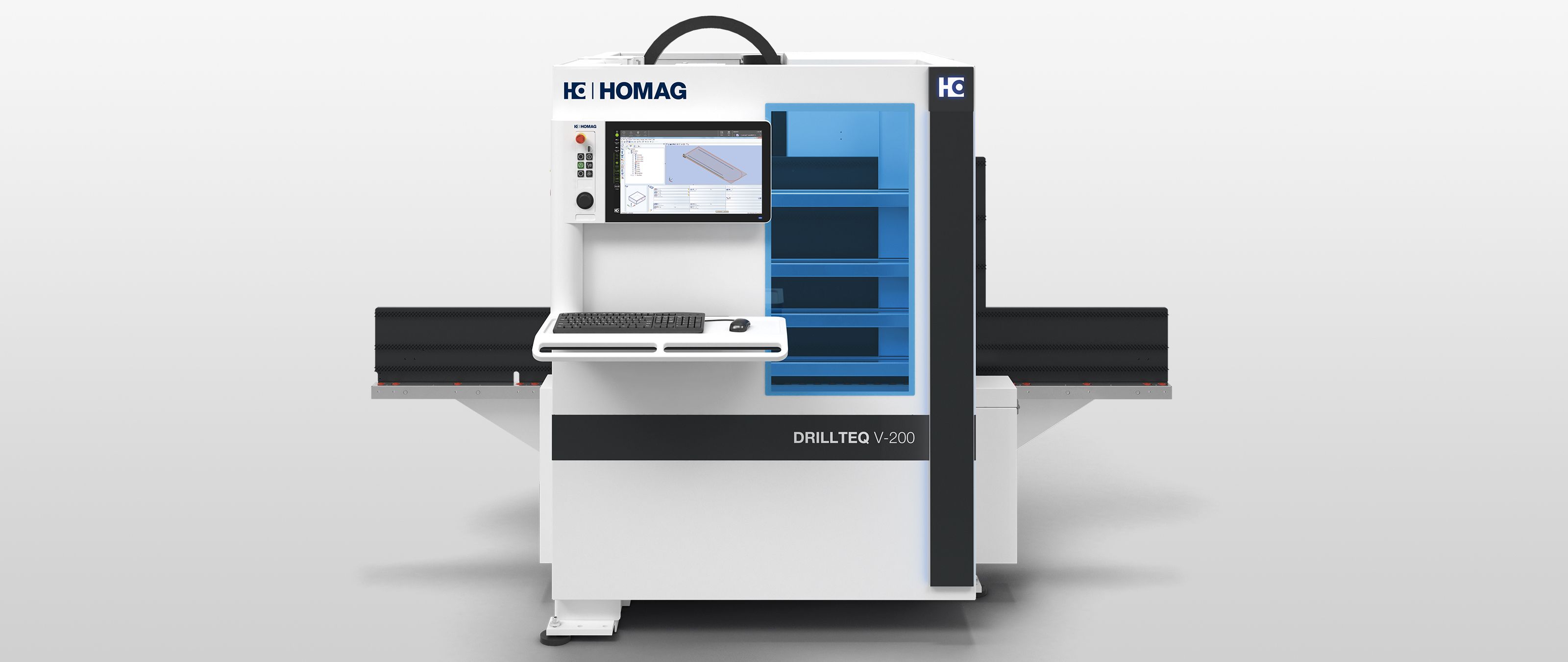

- WoodWOP / MPR files - Weeke BHX 055, Homag Drillteq V-200, Homag CENTATEQ P-110

File formats for CNC wood panel processing machines explained

CNC machines are infinitely versatile but the setup time can be long and this can kill the economics of one-off jobs.

We aim to provide you with files that you can run immediately while standing in front of the machine.

For this you need a file in the format the machine expects. For Homag machines this will be a .MPR file (WoodWOP) and for Felder this will be a .TCN file (TpaCAD).

The crucial feature of MPR and TCN files is that they contain the complete instructions required to command the machine. For example drill a 35mm diameter hole at 100mm from one edge and 22.5mmm away from the adjacent edge. The file contains:- the feature to machine e.g. a hole

- the tool to use e.g. a 35mm diameter drill bit

- feed speeds e.g. 'Slow-Fast-Slow'

- the toolpath e.g. should the tool be centred or be offset by the diameter of the tool

A common file format such as Autocad DXF contains only the first element in this list - the feature to machine. To work out the rest some kind of software package such as Homag WoodWOP or Biesseworks is required to postprocess the DXF and generate the toolpath, tool numbers etc.

With our service and the files it generates you don't need anything else. Our files contain all the information the machine needs. You can transfer the file to the machine using a USB stick and run it immediately.